Phone:

Introduction: DescriptionsThe dry granulator adopts continuous feeding and dischaging,integrates the functions of extrusion,crushing and granulation,and directly presses powdery materials into granules.It is especially suitable for granulating materials that are …

The dry granulator adopts continuous feeding and dischaging,integrates the functions of extrusion,crushing and granulation,and directly presses powdery materials into granules.It is especially suitable for granulating materials that are wet,hot,easy to decompose,fail or agglomerate.It has been widely used in pharmaceutical,food,chemical and other industries.In the pharmaceutical industry,granules made by dry granulator can be directly tabletted or filled into capsules.

Raw materials of dry granulator can be fed by hand,elevator or vacuum feeder.During automatic feeding,the material level sensor monitors the material level in the hopper in real time and automatically adjusts the feeding speed.The powder is scattered in the hopper and quantitatively transported to the feeding port of the pressure wheel through the horizontal feeding screw.

The powder is pressed into sheets by a pressing wheel,and the gap between the pressing wheels is accurately adjustable to meet the requirements of different sheet thicknesses.According to the powder properties,smooth wheel,reticulate wheel and straight wheel can be selected to meet the forming requirements.After being pressed into tablets and pre-crushed,the tablets enter a granulation mechanism.

According to the requirements of grain collection,the whole grain net with different apertures can be selected,and the gap between the whole grain wheel and the whole grain net can be adjusted.According to the property of the material,spiral or hob grading wheels can be selected.The whole mesh can also be equipped with woven mesh or punched mesh plate.

An aggregate port and a discharge port are arranged.The aggregate port collects a small amount of uncompressed raw materials in the triangle area.The discharge port is equipped with a vacuum discharge assembly with a respirator to facilitate vacuum delivery to the screener.

1.Dry granulation:the three processes of powder tabletting,shredding and granulation are designed into a whole.

2.The granulation process is relatively simple,no water or solvent is needed,no drying is needed,and stable particles can be obtained after granulation.

3.The pressure wheel is equipped with a water cooling system to ensure that the temperature of the pressure wheel and materials is not higher than the process requirements.

4.The overall modular design,compact structure,improve the utilization rate of space.

5.The power zone is separated from the working zone to prevent cross contamination.

6.Horizontal feeding structure and exposed installation of extrusion system facilitate cleaning and maintenance.

7.Conform to GMP requirements.

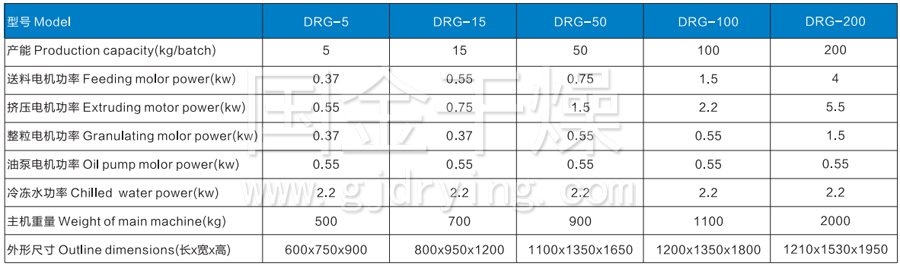

Technical Parameter

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…

Most of China like to eat rice, and rice also accounts for a large proportion of my countrys grain cultivation. With the renewal of agricultu…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…