Phone:

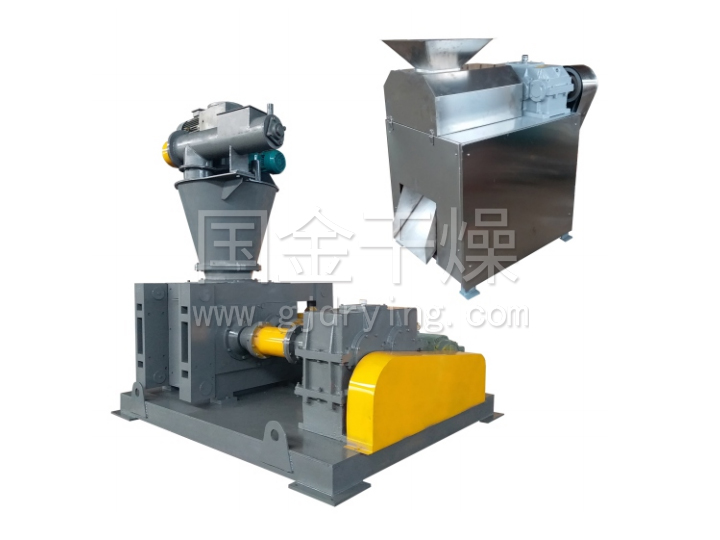

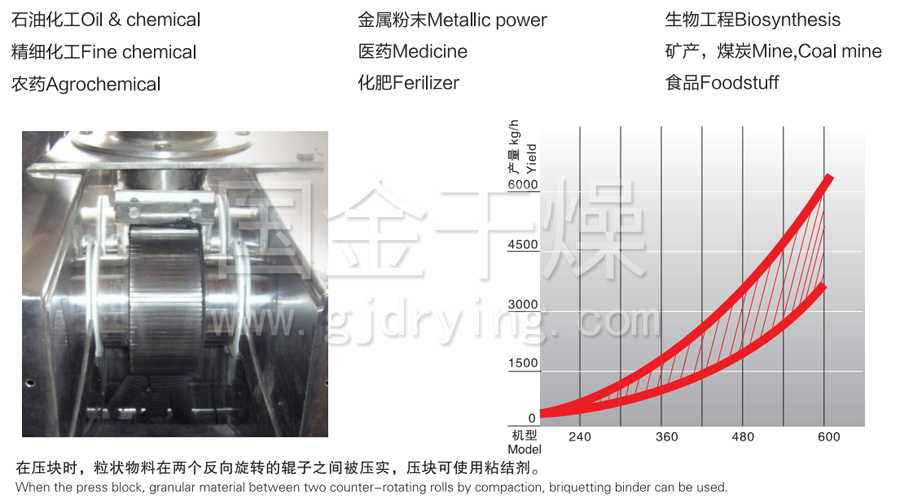

Introduction: Descriptions1.Chemical Dry Roller Granulator adopts dry extrusion technology,which is suitable for water cut.The powder less than 2%is compressed into tablets,and then crushed,granulated and sieved Art,make pieces of bulk materials into granular mater…

1.Chemical Dry Roller Granulator adopts dry extrusion technology,which is suitable for water cut.The powder less than 2%is compressed into tablets,and then crushed,granulated and sieved Art,make pieces of bulk materials into granular materials that meet the use requirements.

2.Dry roll granulation mainly relies on external pressure to force the material to pass through two.A reverse rotating roller gap,compressed into pieces.During the rolling process,the material.The actual density can be increased by 1.5-3 times,thus reaching certain strength requirements.

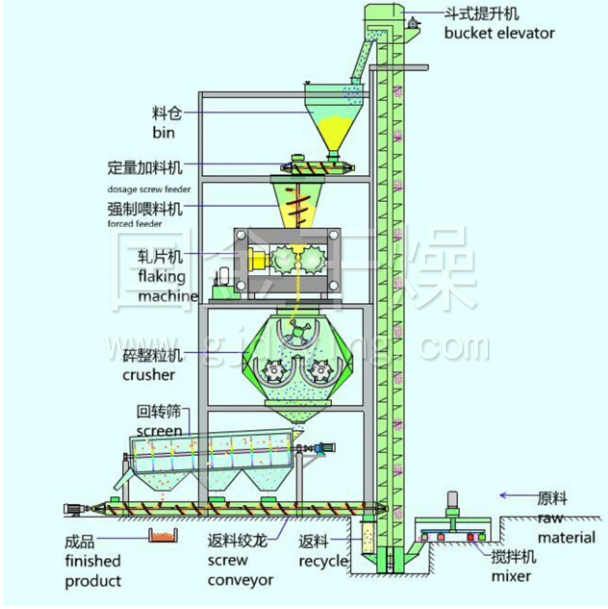

1.Various dry powder materials are added from the top of the equipment,degassed and pre-pressed by spiral into two equal rollers,the rollers rotate relatively,the materials are forced to be sent between the two rollers,the rollers bite the materials into the nip:the materials are compressed,and after the materials pass through the compression zone,the surface tension and gravity of the materials naturally separate them.The separated finger-shaped briquettes enter the granulator to be crushed by the rotary knife row,and the crushed materials enter the granulator to be sieved by the rotary vibration sieve through the rolling knife row.Qualified products are transported to the finished product warehouse by a conveyor.The

powdery undersize material is sent back to the raw material bin for secondary rolling by a conveyor,and the extrusion pressure can be adjusted by the pressure of a hydraulic oil cylinder according to the

needs of granulation operation.

2.Sheet,strip and oblate materials can be obtained by changing the grooving form of roller surface.

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…

Most of China like to eat rice, and rice also accounts for a large proportion of my countrys grain cultivation. With the renewal of agricultu…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…