Phone:

Introduction: Overview of catalyst materialsThe role of catalysts in chemical reactions is called catalysis. Catalysts are also called catalysts in the industry.The composition, chemical properties and quality of the catalyst itself will not change before and after…

The role of catalysts in chemical reactions is called catalysis. Catalysts are also called catalysts in the industry.

The composition, chemical properties and quality of the catalyst itself will not change before and after the reaction; its relationship with the reaction system is like the relationship between a lock and a key, with a high degree of selectivity (or specificity). A catalyst does not catalyze all chemical reactions. For example, manganese dioxide catalyzes the thermal decomposition of potassium chlorate to accelerate the rate of chemical reactions, but it does not necessarily catalyze other chemical reactions. Some chemical reactions are not only catalysts. For example, potassium chlorate can be catalyzed by the thermal decomposition of magnesium oxide, iron oxide, copper oxide, and so on. Moreover, a chemical reaction does not have only one catalyst. For example, red brick powder or copper oxide can also be used as a catalyst when preparing oxygen from potassium chlorate.

The catalyst double-cone rotary vacuum dryer is a double-cone rotary tank. When the tank is in a vacuum state, steam or hot water is introduced into the jacket for heating. The heat contacts the wet material through the inner wall of the tank, and the wet material absorbs heat. The evaporated water vapor is pumped away through the vacuum exhaust pipe by the vacuum pump. Since the tank body is in a vacuum state, and the rotation of the tank body continuously turns the material up and down, the drying speed of the material is accelerated, the drying efficiency is improved, and the purpose of uniform drying is achieved.

The catalyst double cone rotary vacuum dryer is a new type of dryer that integrates mixing and drying. The condenser, vacuum pump and dryer are matched to form a vacuum drying device. (If the solvent needs to be recovered, the condenser can be omitted) The design of this machine is advanced. At the same time, because the material rotates when the container itself rotates, but the material does not accumulate on the container, the heat transfer coefficient is high and the drying rate is high, which not only saves energy.

The catalyst double cone rotary vacuum dryer is a new type of dryer that integrates mixing and drying. The condenser, vacuum pump and dryer are matched to form a vacuum drying device. This machine has advanced design, simple internal structure, easy cleaning, all materials can be discharged, and easy operation. Can reduce labor intensity and improve working environment. At the same time, because the material rotates when the container itself rotates and there is no material accumulation on the wall of the container, the heat transfer coefficient is high, the drying rate is large, not only energy saving, but also the material is dried uniformly and fully, and the quality is good. It can be widely used for drying materials in pharmaceutical, chemical, food, dye and other industries. It meets the requirements of the "GMP" of the Drug Administration Regulations.

● When oil is heated, it adopts automatic constant temperature control, which can dry biochemical products and mineral raw materials, and the temperature can be between 20 and 160 ℃.

● High thermal efficiency, more than 2 times higher than ordinary oven.

● Indirect heating, the material will not be contaminated and meet the requirements of "GMP". The equipment is easy to maintain and operate and easy to clean.

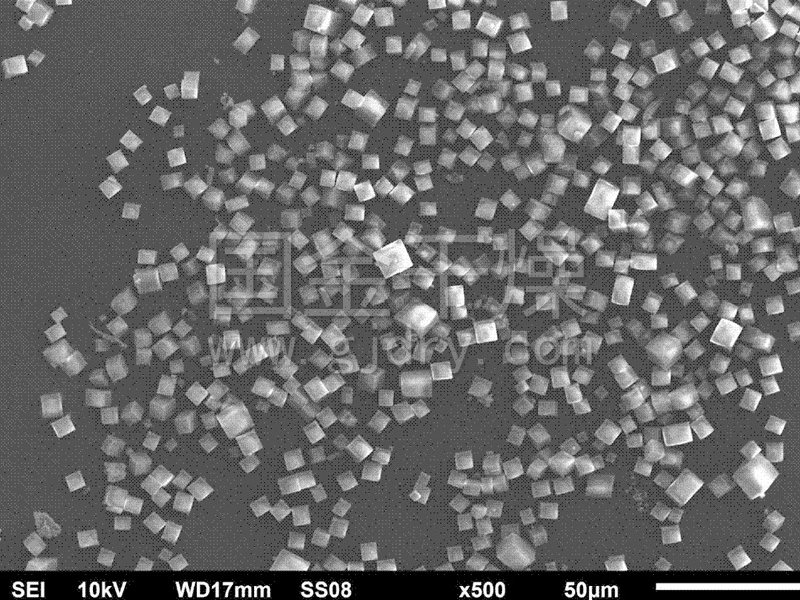

It is suitable for the concentration, mixing, drying of powder, granular and fibrous materials in the chemical, pharmaceutical, food and other industries, and materials that require low-temperature drying (such as biochemical products, etc.). It is more suitable for easy oxidation, volatile, heat sensitivity, strong stimulation, Drying of toxic materials and materials that are not allowed to destroy crystals.

Drying equipment is very widely used in industrial testing. Many fields require the use of drying equipment. Similarly, drying equipment also…

As the worlds energy consumption is increasing year by year, the burning and utilization of coal, which is a primary energy source, releases …

The hot air circulation oven is composed of angle steel, stainless steel plate and cold steel plate. The thermal insulation layer is filled w…

Most of China like to eat rice, and rice also accounts for a large proportion of my countrys grain cultivation. With the renewal of agricultu…

The ZPG special spray dryer for Chinese medicine extract is a special spray dryer. The high-speed centrifugal spray device for Chinese medici…

The general requirements of the granulator used in the calcium carbonate industry are high thermal efficiency, low energy consumption, simple…